Pagoda And Pagoda Roof

In the picture of the Glen Garioch Distillery, you can see the classic pagoda roofs very well. These can be seen on the buildings of many Scottish Whisky distilleries. But what are these pointed, Asia-looking roofs doing on a Whisky distillery? A pagoda is actually a multi-storey tower, whose individual floors are usually separated from each other by cornices or eaves. This way of building is especially widespread in Asia. At the end of the 19th century, this style was also modern in Europe and so Charles Chree Doig built Scotland’s first pagoda in 1889 at the Dailuaine Distillery. The pagoda roofs can be found on the distillery buildings, which contain the kiln, i.e. the malt floor. Here, the germinating barley was spread out and dried over a fire. Good ventilation is essential in this drying process, as the temperature in the kiln must not exceed 55 degrees Celsius in order not to destroy the enzymes in the grain. Today, kilns with their typical pagoda roofs have mainly decorative purposes: only a few distilleries still malt their barley in-house.

Crafting The World’s No 1 Scotch

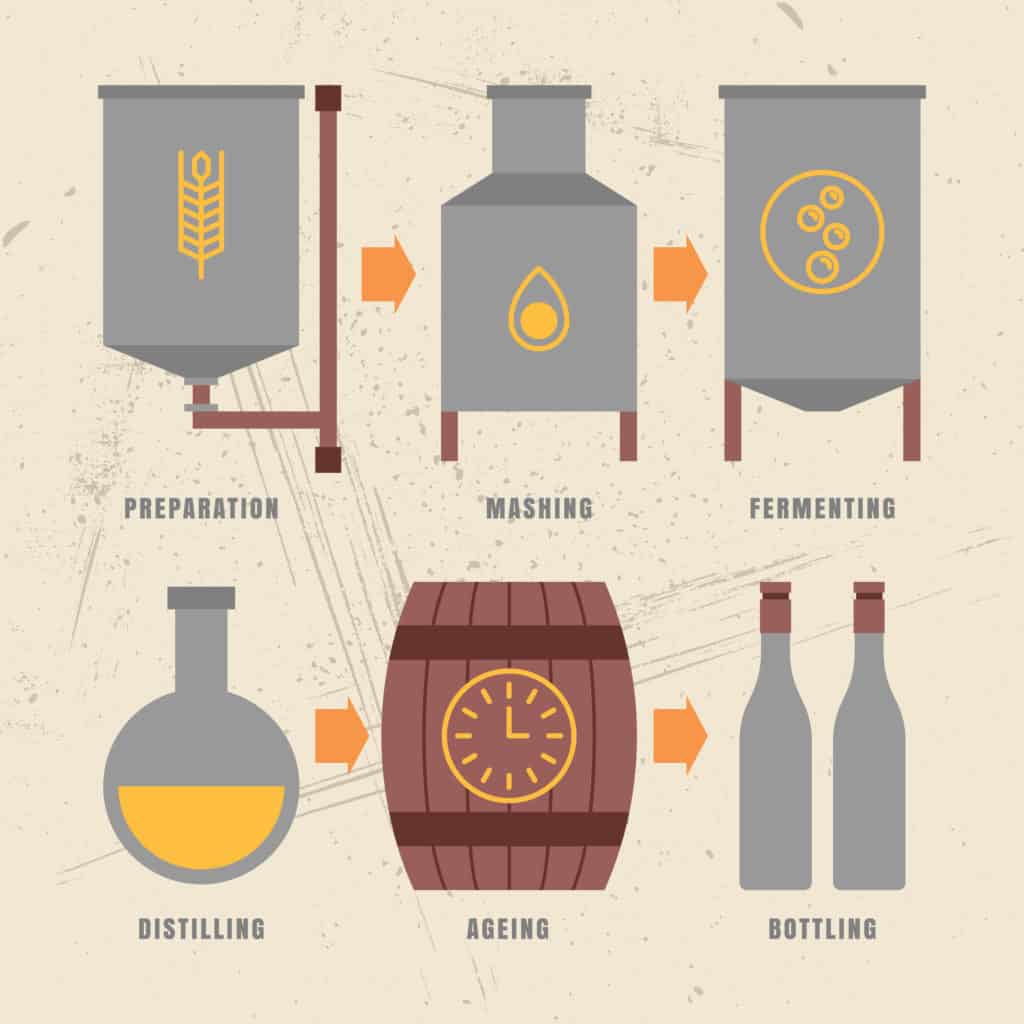

Making Scotch Whisky is a much-honed craft that has been refined over time from a cottage industry into a precision process. Many elements shape the final flavor and character of a whisky, including the type of grains and yeast used, the shape of the still, the cask and the length of time its matured in it. This is how Scotland has come to produce such a variety of whiskies, from the bold smokiness of west coast malts to the gentler flavors of Highland whiskies. Here you can discover how whisky is made.

Why Are Enzymes Important In Moonshine Production

As we have already seen, enzymes break down starch to fermentable sugars in mash, which is then fermented to produce alcohol. The alcohol is then distilled to produce moonshine. Simply put, without enzyme action, fermentation cannot take place. In whiskey production, malted barley is the most commonly used enzyme. Barley is the most commonly used grain owing to its high diastatic power. This means that it has a higher ability to break down starches into fermentable sugars.

Some distillers use commercial enzymes particularly in the production of malt-less whiskeys. The advantage that commercial enzymes offer is that they have higher conversion hence yielding more alcohol from mashes that do not have barley. Another advantage of using commercial enzymes instead of malt is that smaller quantities of enzymes are used compared to the large quantities of malt for manageable storage and handling in addition to significantly reduced raw materials. Commercial enzymes are however not allowed in the production of scotch-whiskey.

Also Check: Costco Skyy Vodka

Starting With The Basics: Barley

Every single malt Scotch whisky begins with barley, a humble grain. In the past the barley was grown on the fields of the distillery but these days it is much more likely to be purchased in bulk or shipping in from overseas.

Different varieties of grape are used in the wine production and in a similar way, a number of barley varieties are used in the distillation of single malt whisky such as Chariot, Optic and Golden Promise. However, it must be barley that is used in order to call the finished product malt whiskey if it is rye, corn, buckwheat or maize then the result is not considered malt whiskey.

Sprouting The Corn And Making The Mash

Sprouting kernel corn is a simple matter of getting it wet and allowing small sprouts to grow. Once the corn is sprouted, it’s ready to be made into a mash. A mash is a combination of warm water and grain. The enzymes in the mash break down the starch in the grain and produce sugar.

Don’t Miss: Who Makes Members Mark American Vodka

Getting Your Fermentation Just Right

“At first, it will go from the sweetest oatmeal you’ve ever had, to something that is fairly sour. That’s the first sign that you are converting your sugar into alcohol. The absence of sugar means the yeast has done its job,” Katz said, describing the fermentation process. On a larger scale, this should only take a few days. But at home, on a smaller scale without precise temperature management, it could take a little bit longer. Unfortunately, when you’re working from home, it’s an inexact science. Again, a home brewing kit might be able to help you keep things consistent and a little more precise. You probably shouldn’t ferment for more than a week, and you can certainly taste test your product along the way as much as you’d like. Katz even recommends heading to your local distillery to figure out how your mash should taste before you start the distilling process.

Five Distillers You Should Know

Meet the brains behind some of your favorite whiskies, the folks who tweak the stills, innovate products, and ensure quality behind some of the world’s most beloved brands. They’re often out hosting events and tastings too, so say hello next time they’re in your town.

Jimmy Russell, Master DistillerWild Turkey Range, Russell’s ReserveFor over 61 years, Jimmy Russell has been making whiskey. As such, he’s the longest-tenured active master distiller in the world. The most famous brand he’s behind Wild Turkey you’ve probably tasted, so check out his Russell’s Reserve six-year-old small batch Kentucky straight rye whiskey. Russell, along with his son, hand selects casks to marry and bottle. The whiskey is distilled at a lower proof than most bourbons in Kentucky, which means that during final bottling, less water is needed to bring the proof down, as is often customary.Still style: Column

Mike Miyamoto, Master DistillerSuntoryTrace the elegance, finesse, and popularity of Japanese whiskies to the mastery of a variety of stills. Master distiller Mike Miyamoto continually fine-tunes all parts of the whisky-making process to subtly improve the taste of his whisky over time. “If the Yamazaki you hold in your hand tastes the same in ten years, we have failed,” he told me.Still style: Pot and Column

Recommended Reading: Mix With Titos

The Development Of Taste During Cask Maturation

The origin of the casks is crucial for the taste of the Whisky. Glenfiddich predominantly matures their Whiskies casks made from American white oak that has previously been used to mature Bourbon Whiskey. In contrast, distilleries like Macallan or Bowmore use mainly casks that held Spanish Sherry before. One Malt Whisky from Springbank became a legend: it was matured in ex-rum casks from the Caribbean and took on a green colour.

A bit less important for the taste of the Whisky is the place of maturation. The old warehouses are dark and have earth floors. The casks are stored on oak beams and are stacked on top of each other in 3 to 6 rows. Modern warehouses have concrete floors so the casks can be moved with forklifts. Until the end of the last century, the casks were stored lying on steel racks. Nowadays the casks are mostly stored upright on pallets. Whisky matures differently in the highlands than on the islands, since there are hot summers and cold, snowy winters in the highlands, while the gulf stream provides for a mild climate on the islands and at the coast.

How Commercial Moonshine Mash Is Made

Before we get started, a reminder: Distilling alcohol is illegal without a federal fuel alcohol or distilled spirit plant permit as well as relevant state permits. Our distillation equipment is designed for legal uses only and the information in this article is for educational purposes only. Please read our complete legal summary for more information on the legalities of distillation.

There are three distinct ways that a commercial distiller would likely make a moonshine mash. The first two methods are based on traditional corn whiskey recipes. The third method is a cheap and easy , but isnt recommended for someone serious about making a high quality product.

Keep in mind that crafting moonshine combines both science and art. A novice commercial distiller or a distillery that focuses on making fast, cheap booze for the purpose of flavoring would start with the 3rd recipe listed here . A distillery more focused on higher quality spirits with more complex characteristics would likely chose to use the all-grain “corn whiskey recipe. A middle point would be the “thin mash” recipe.

You May Like: Bacardi Drink Mix

Whisky Making On A Small Scale

Now that you know how whiskey is made at a manufacturer level, it will easier for you to understand how to make whiskey at home. First, you have to choose your base, for which youve got several options to choose from including rye, wheat, barley, corn or a blend of different grains.

But if youre just getting started with making whiskey, then it may be best to get started with corn the easiest ingredient to get your hands on. Corn also is one the few home making whiskey ingredients that yields the most sugar, which is something that you ideally want.

And given that you probably need roughly 10 lbs of corn to make a reasonable volume of whiskey at home. it will be less expensive to buy to make approximately five gallons of final product.

Homemade Whiskey Recipe And Technology

The following recipe will let you make homemade whiskey according to a classic technology, which is used in Ireland and Scotland. It resembles usual moonshining quite a bit, but also includes one additional stageâoak infusion, which lasts 6 months or more. This time is necessary to make a good alcoholic drink.

To make homemade whiskey which is very similar to Scottish or Irish original drinks, youâll have to travel a long way, but the result will be worth the effort.

Also Check: Jim Beam Review

How Whiskey Is Made: Water A Key Whiskey Ingredient

Whiskey enthusiasts who get the chance to taste-test with a master distiller may notice that at some point hell add some water to the glass. Doing so is said to open up the flavors and aroma of the drink. Even the word whiskey stems from the Gaelic word uisge, meaning water. But why is the water so important? Scientists say water improves the taste because alcohol molecules and those that determine the whiskeys flavor stick together. So if wine pairs well with cheese, then whiskey pairs well with water. And the reason starts with how whiskey is made.

Whiskey Distilling: Stages And Tips

If you are new to the process of producing good quality whiskey, you may be wondering where to start? What may initially seem like a long-winded and complicated to master process is indeed worth taking the time to learn from, mainly when the result derives in that perfect bottle of your very own whiskey drink!

However, to get to this final stage, you need to make sure that you follow the best method, similar to those in the big named distilleries if you are after some of the most significant effects in your beverage. By mastering the primary whiskey distilling stages, you could soon be distilling your high end and high-quality fantastic tasting whiskey in no next to no time at all.

There is a three-stage process involved to distilling the water needed for that perfect glass of whiskey, including mashing the water, reducing the water and cooling the water, which will give you that competitive edge when brewing this beverage for yourself on a larger scale perfect for those working in the beverage industry.

Don’t Miss: What Mixes With Tito’s Vodka

How To Make Whisky

Let us show you how whisky is made, and what makes a good whisky. An ancient process thatâs been refined over centuries, and one in which so many factors can come to influence the flavour of the final product. Itâs not quite alchemy, but the craft of our Master Distillers yields something akin to liquid gold.

Distilling : How Whiskey Is Actually Made

Unless you’ve been living without the internet, you surely know that Star Wars season is upon us. If you are lucky enough to live in Manchester, England, check out the replica of Chalmun’s Spaceport Cantina, the “no-droids allowed” drinking hole located in the pirate city of Mos Eisley on the barren planet of Tatooine. In the film, a bevy of copper pipes run along the ceiling and more pipes run along the wall. Because Tatooine is a dry planet, my best guess is that distilled spirits would have been the most popular libation there: They could have thrown any old sugary, starchy substance into a pot with water and yeast to ferment and later distill. Distillation would have spread across the Star Wars universe like it spread throughout the continents on Earth, either for health reasons, sanitary reasons, or pure enjoyment. On Earth, we can pinpoint the arrival of distillation somewhere between the years 1 AD and 3 AD, but no one can be sure. But what exactly is distillation?

Don’t Miss: Svedka Dragonfruit Melon Recipes

Can You Make Whiskey At Home

Unfortunately, making whiskey at home is illegal in the United States. In fact, the distilling of any spirit at home is illegal under federal law. You can make wine and beer at home, but liquors like vodka, gin, moonshine, and whiskey cannot be made at home for personal use.

It is perfectly legal to own a still, which is what whiskey is distilled in. You can make essential oils, perfume, or even distilled water in it, so long as youre not producing liquor. In fact, its even legal to make ethanol for home fuel uses, provided you have a permit. Making whiskey at home is possible but not recommended, as it is illegal and potentially dangerous.

The Important Job Of The Stillman

The pot stills must be replaced after 15 to 25 years when the wall thickness of the copper has decreased to 4 to 5 mm. The stillman makes sure that the shape of the still is not changed because this would lead to a change in taste, too.

The story goes that some stillmen even replicate dents and bumps in the new pot stills, but thatâs just a fairytale. The outlets of the stills are sealed by the government so no thirsty Scot can get his hands on untaxed spirit. In order to assess the quality of the low wines and the spirit anyway, the pipes are run through a case usually made from glass and polished brass, the spirit and sample safe. The stillman checks the quality and runs the spirit back into the still or into the spirit receiver using valves and levers.

All this is done only by visual inspection and with measuring instruments. A stillman cannot taste the spirit! In the sample compartment of the safe he can measure the temperature and take samples in order to measure the density of the spirit with hydrometers. The stillmanâs most important task is to cut off the middle cut properly. At this stage, it is decided whether the batch is going to be just good or excellent. The foreshots take about 30 minutes to run through. The middle cut is then extracted for about 3 hours. The last runnings of the distillation, called feints, are led back into the spirit still. They contain higher concentrations of propanol, isopropanol and fusel oils.

Don’t Miss: Member’s Mark American Vodka Review

What Gives Scotch Whisky Its Distinctive Flavour And Bouquet

The distilling process itself is one factor. ScotchWhisky, after it has been distilled. contains not onlyethyl alcohol and water but certain secondaryconstituents. The exact nature of these is not fullyunderstood. but it is believed they include some of theessential oils from the malted barley and other cerealsand substances that derive from the peat. The amount ofthese secondary constituents retained in the spiritdepends upon the shape of the still and the way it isoperated and also on the strength at which the spirit isdrawn off. Grain Whisky, because of the process bywhich it is made, contains fewer secondary constituentsthan Malt Whisky and is accordingly milder in flavourand aroma.

The natural elements of water, peat and the Scottishclimate all certainly have a profound effect on the flavourof Scotch Whisky. Water is probably the most importantsingle factor and a source of good, soft water is essentialto a distillery. Peat, which is used in the kiln or oven inwhich the malt is dried. also has an influence that can bedetected in the ‘peaty’ or smoky flavour of many ScotchWhiskies. The Scottish climate is extremely importantparticularly when the whisky is maturing. At this stagethe soft air permeates the casks and works on the whisky,eliminating harsher constituents to produce a mellowwhisky.

The Quintessencial Kentucky Water

One of the most important parts of how is bourbon made is adding Kentucky water. In fact, Kentucky water is potentially the most critical ingredient in bourbon. Kentucky water is hard, limestone-packed water that bonds nicely during the fermentation process.

Many people across the states have tried to replicate the flavor of Kentucky Bourbon, but they cannot do so because they lack Kentuckys hard water.

Read Also: Scotch And Gout

Water Throughout The Process

The first ingredient in whisky is water. To make whisky, distillers need lots of pure, cold water. It’s so important a lot of distilleries talk about how important their water source is. Many say they chose the site of their distillery because there was a perfect water source nearby. While it may be a key part of a distillery’s story and history, the impact water has on a whisky’s flavour is debatable. Some experts say the water actually has only little impact on the taste of whiskies.

Water has two separate roles in whisky production. It is an ingredient, but it is also needed in whisky production itself. You need hot water as part of mashing, to cook the grains, and it is also used to heat the stills at some distilleries. Cold water helps convert alcohol vapours created during distillation back to liquid form. Water is sometimes added to new-make spirit to reduce its strength before its put into casks. And again, adding water adjusts alcohol strength before bottling. So, if you have a bottle of whisky thats 40% ABV, what youre drinking is 40% alcohol and 60% water. A key exception is cask strength whisky, which has no added water before bottling. You can read about adding water to whisky here.