Maturation: Oak Barrel Aging

The final major step in how whisky is made is barrel aging. All whisky requires it to some extent. Without oak aging, the final product is really just moonshine or strong-flavored vodka. Sometimes this clear spirit will be bottled and labeled white whiskey or white dog. Without oak contact and time, this stuff doesnt resemble whisky.

The processes involved in barrel aging are complex and deserve their own post. Check out part three of this whisky basics series: Oak Casks and Aging Whisky.

Sprouting The Corn And Making The Mash

Sprouting kernel corn is a simple matter of getting it wet and allowing small sprouts to grow. Once the corn is sprouted, it’s ready to be made into a mash. A mash is a combination of warm water and grain. The enzymes in the mash break down the starch in the grain and produce sugar.

The Remaining Liquid Is Distilled

As The Whiskey Professor explains, there are two separate distilling processes that the fermented mixture must go through before barreling. The first distillation process happens before the liquids and solids are separated. Once the mash is fermented and has a low-alcohol content, it’s known as distillers’ beer. It’s sent into a still, where it’s heated, making the alcohol vapors rise. These vapors travel through a tube that condenses the vapors, turning them back into liquid. This higher-proof liquid is reserved, while the remaining mixture that’s left behind will be used elsewhere .

The reserved, higher-proof liquid is sent on to the second distillation process in a “doubler,” and the proof increases even further. This liquid is almost ready for barreling and can be held in a retention tank until that time.

But what about all those liquids and solids that the vaporized alcohol left behind?

Read Also: Does Cayman Jack Margarita Have Tequila

History And Traditional Usage

Malted grains have probably been used as an ingredient of beer since ancient times, for example in Egypt , , and China.

In countries, a sweet paste made entirely from germinated wheat is called in , samanak in , or sümölök , which is prepared for in a large pot ” rel=”nofollow”> kazan). A plate or bowl of samanu is a traditional component of the symbolising affluence. Traditionally, women have a special party to prepare it during the night, and cook it from late in the evening until the daylight, singing related songs. In and , they sing: Samanak dar Jsh u m Kafcha zanm Dgarn dar Khwb u m Dafcha zanm . In modern times, making samanu can be a family gathering. It originally comes from the Great Persian Empire.

, or Easter Porridge, is a traditional food. Cooked from rye malt and flour, mämmi has a great resemblance to saman. Today, this product is available in shops from February until Easter. A survey in 2013 showed that almost no one cooks mämmi at home in modern-day .

Malting is the process of converting barley or other cereal grains into malt for use in brewing, , or foods, and takes place in a , sometimes called a malthouse, or a malting floor. The cereal is spread out on the malting floor in a layer of 8 to 12 cm depth.

As of 2014, the largest malting operation in the world was Malteurop, which operates in 14 countries.

Water Throughout The Process

The first ingredient in whisky is water. To make whisky, distillers need lots of pure, cold water. It’s so important a lot of distilleries talk about how important their water source is. Many say they chose the site of their distillery because there was a perfect water source nearby. While it may be a key part of a distillery’s story and history, the impact water has on a whisky’s flavour is debatable. Some experts say the water actually has only little impact on the taste of whiskies.

Water has two separate roles in whisky production. It is an ingredient, but it is also needed in whisky production itself. You need hot water as part of mashing, to cook the grains, and it is also used to heat the stills at some distilleries. Cold water helps convert alcohol vapours created during distillation back to liquid form. Water is sometimes added to new-make spirit to reduce its strength before its put into casks. And again, adding water adjusts alcohol strength before bottling. So, if you have a bottle of whisky thats 40% ABV, what youre drinking is 40% alcohol and 60% water. A key exception is cask strength whisky, which has no added water before bottling. You can read about adding water to whisky here.

You May Like: What To Mix With Jack Daniels Cinnamon Whiskey

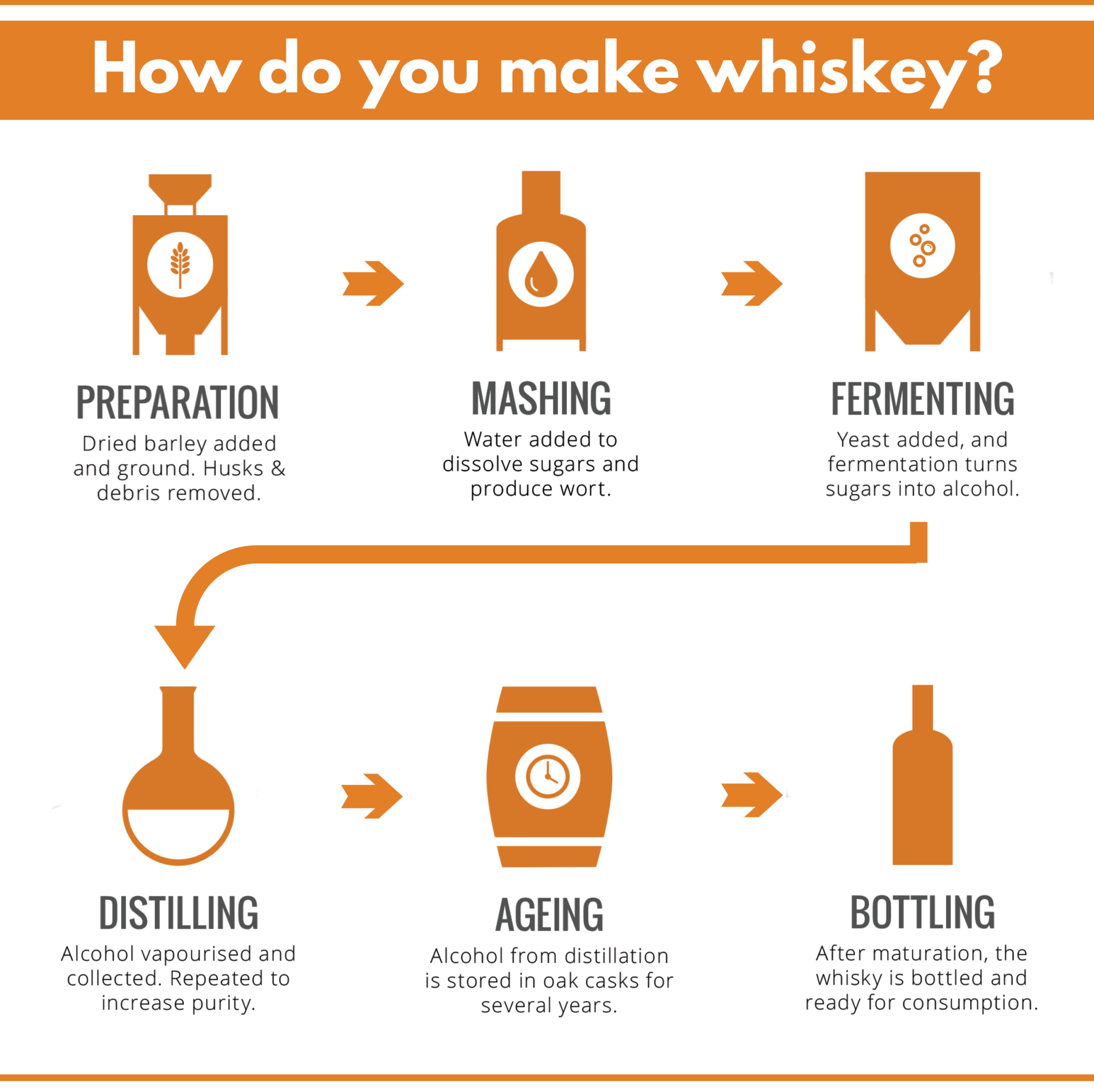

How Is Whisky Made

The principals for the distillation of whisky have changed little over the last 200 years. Just three basic ingredients are needed – water, barley and yeast. Technology now aids production, but traditionally there are five stages to the process – malting, mashing, fermentation, distillation and maturation. Here we go through and expalin each of these important stages.

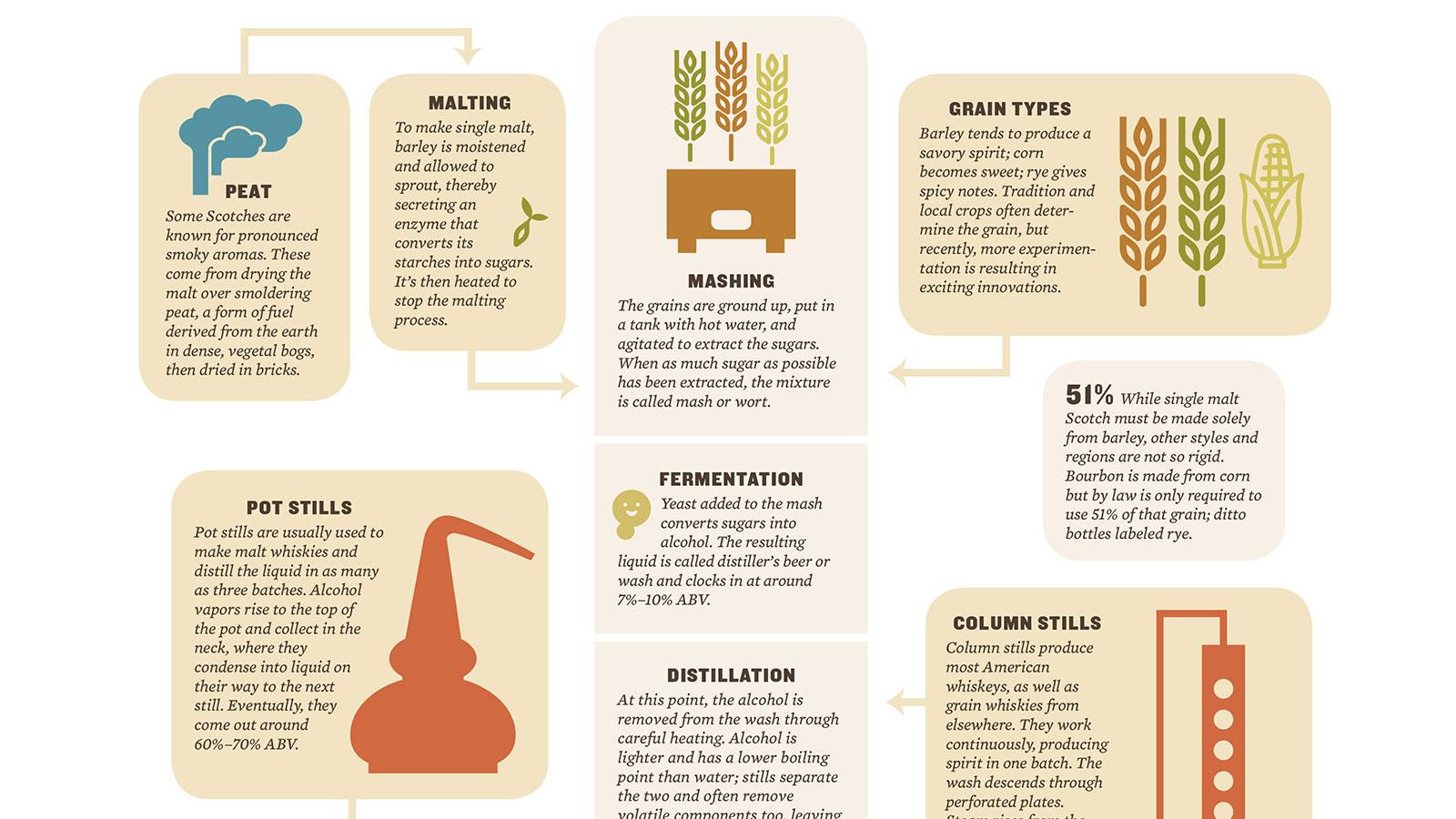

Step 1 – Malting Barley contains starch and it is this starch which needs to be converted into soluble sugars to make alcohol. For this to occur, the barley must undergo germination and this first part of the prodess is called ‘malting’. Each distiller has their own preference about the type of barley they buy, but they need a type that produce high yields of soluble sugar. The barley is soaked for 2-3 days in warm water and then traditionally spread on the floor of a building called a malting house. It is turned regularly to maintain a constant temperature. This is also carried out on a commercial scale in large drums which rotate.

When the barley has started to shoot, the germination has to be stopped by drying it in a kiln. Traditionally peat is used to power the kiln and it is at this point where the type of peat used and length of drying in the peat smoke can influence the flavour of the final spirit. The barley is now called ‘malt’ and this is ground down in a mill, with any husks and other debris being removed.

So What Is Whiskey Made From

So, after all that, what is whisky made from? Well, it depends on what kind of whisky youre making. I did warn you that it wasnt straight forward! Two key ingredients are water and yeast. The third is some kind of cereal. In scotch, this is malted barley. In bourbon, 51% has to be corn. The fourth and fifth elements are time and wood. These aren’t ingredients in the traditional sense, but they do play a key role. You may enjoy our article about dunnage warehouses here.

Recommended Reading: Where Can I Buy Tin Cup Whiskey

How To Make Whiskey

wikiHow is a wiki, similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, 15 people, some anonymous, worked to edit and improve it over time.wikiHow marks an article as reader-approved once it receives enough positive feedback. This article has 16 testimonials from our readers, earning it our reader-approved status. This article has been viewed 795,392 times.Learn more…

Store bought whiskey can be incredibly tasty, especially if it comes from a local brewhouse or high-quality distillery. However, preparing your own whisky at home will allow you to control exactly what goes into it and find a flavor that suits you perfectly.

How Whisky Is Made

Although whiskey is a complex spirit which contains many different flavours and aromas, the process for making it is simple. In fact, you might be surprised to discover that making whiskey only requires three basic ingredients water, yeast, and grains.

However, the ways these three ingredients are processed, distilled, and aged can vary greatly. The type of whiskey being produced, the region where it is being produced, and the distillers personal approach to whiskey can all change how it is made.

To help you better understand what you are drinking, this post will explain how whiskey is made, all the way from water/yeast//grains to your glass.

Read Also: Which Hard Seltzer Has Vodka

Fermentation: Beer Before Whisky

At this stage in the whisky-making process there is still no alcohol. For that, yeast will be needed. The sweet wort will be placed into a washback or an open fermenter and already contains some ambient yeast.

The distiller will typically add either commercially available distillers yeast , their own proprietary yeast, or even ambient yeast. The yeast used for distillation can usually handle a higher alcohol content than the yeast used for brewing beer.

The final fermented beer, or wash, will usually be between 8% and 14% abv. Beer is an appropriate term, because at this point: the fermented brew is literally beer without hops. Its pretty cool that whisky production begins with the process of brewing beer!

The Important Job Of The Stillman

The pot stills must be replaced after 15 to 25 years when the wall thickness of the copper has decreased to 4 to 5 mm. The stillman makes sure that the shape of the still is not changed because this would lead to a change in taste, too.

The story goes that some stillmen even replicate dents and bumps in the new pot stills, but thatâs just a fairytale. The outlets of the stills are sealed by the government so no thirsty Scot can get his hands on untaxed spirit. In order to assess the quality of the low wines and the spirit anyway, the pipes are run through a case usually made from glass and polished brass, the spirit and sample safe. The stillman checks the quality and runs the spirit back into the still or into the spirit receiver using valves and levers.

All this is done only by visual inspection and with measuring instruments. A stillman cannot taste the spirit! In the sample compartment of the safe he can measure the temperature and take samples in order to measure the density of the spirit with hydrometers. The stillmanâs most important task is to cut off the middle cut properly. At this stage, it is decided whether the batch is going to be just good or excellent. The foreshots take about 30 minutes to run through. The middle cut is then extracted for about 3 hours. The last runnings of the distillation, called feints, are led back into the spirit still. They contain higher concentrations of propanol, isopropanol and fusel oils.

Recommended Reading: Does Vodka Have Sugar In It

Single Pot Still Whiskey

is made from a mixture of malted and unmalted barley completely distilled in a pot still within a single distillery. This differs from single malt whiskey through the inclusion of raw, unmalted grain in the mash. This style has also historically been referred to as “pure pot still” whiskey and “Irish pot still whiskey”, with older bottlings and memorabilia often bearing these names. Single pot whiskeys were the most common style of Irish whiskey until the emergence of blends in the 20th century.

Explanations Of The Above Stages:

Malting is a process in which grain is specifically treated to access its sugar. Grain is moistened and allowed to partially sprout, or germinate. The process of malting secretes an enzyme called amylase .The amylase converts the grains starches into sugars. The germination process is cut off when the grain is dried by heating.

Mixing the mash is mixing cooked grains with malted barley and warm water. After several hours, the mixture becomes a turbid, sugar-rich, porridge-like liquid known as mash. The mash is then put in a large tub called a mash tub. It is mixed with hot water and then agitated. Even if not making malt whiskey, some ground malted barley is typically added to help catalyze the conversion of starches into sugars. The mash is also sometimes referred to as wort. As much sugar as possible is extracted from the wort and it then goes on to the fermentation stage.

During the fermentation process, yeast is added to the wort. The yeast eats up the sugars in the wort and converts them into alcohol. The fermentation process takes place in giant vats, often called washbacks. Fermentation takes 48 to 96 hours. Different fermentation times and different yeast strains result in a wide spectrum of flavors in the final whiskey product. The resulting beer-like liquid contains about 7% to 10% ABV before it goes on to the still.

Whiskey Distillery How is Whiskey Made?Image by Bernd Hildebrandt from Pixabay

The two most common types of still are pot stills and column stills.

Read Also: What Kind Of Rum For Rum And Coke

Choosing The Perfect Bourbon Barrel

But back to the alcohol. At this point, the bourbon is waiting in the retention tank for barreling. However, before a distiller can add the bourbon to just any ol’ barrel, they must choose the perfect barrel, which is a whole task in and of itself.

Barrels are produced by coopers and the barrel-making process is just as important to the end bourbon as any other part of the whiskey’s creation. One Eater article looked into the barrel-making process by interviewing the owners of the Adirondack Barrel Cooperage. There, coopers purchase Missouri American oak wood, which is known for being impervious to water and relatively low on tannins thanks to the growing area’s heavy rain and snow. The wood is aged two to five years, then mechanically shaped into the recognizable barrel curvature. After all the wood slats are the right size and shape, a ring is attached, which keeps it all together. Then, the new barrel is heated and charred . After the barrel cools, it’s cauterized, sealed, sanded, and shipped.

And only then is the barrel ready to be filled with bourbon.

Five Distillers You Should Know

Meet the brains behind some of your favorite whiskies, the folks who tweak the stills, innovate products, and ensure quality behind some of the world’s most beloved brands. They’re often out hosting events and tastings too, so say hello next time they’re in your town.

Jimmy Russell, Master DistillerWild Turkey Range, Russell’s ReserveFor over 61 years, Jimmy Russell has been making whiskey. As such, he’s the longest-tenured active master distiller in the world. The most famous brand he’s behind Wild Turkey you’ve probably tasted, so check out his Russell’s Reserve six-year-old small batch Kentucky straight rye whiskey. Russell, along with his son, hand selects casks to marry and bottle. The whiskey is distilled at a lower proof than most bourbons in Kentucky, which means that during final bottling, less water is needed to bring the proof down, as is often customary.Still style: Column

Mike Miyamoto, Master DistillerSuntoryTrace the elegance, finesse, and popularity of Japanese whiskies to the mastery of a variety of stills. Master distiller Mike Miyamoto continually fine-tunes all parts of the whisky-making process to subtly improve the taste of his whisky over time. “If the Yamazaki you hold in your hand tastes the same in ten years, we have failed,” he told me.Still style: Pot and Column

Recommended Reading: How To Sell Vintage Whiskey

/5read To Be An Expert

Raising a toast to celebrate the cherished moments is incomplete without a glass of your favourite drink. Smooth, enticing and punchy, your drink defines your choicesin life. On the World Whiskey day, let’s unwind and find out What makes one spirit different from other. While savouring the smooth taste of your favourite dark spirit, have you ever wondered the difference between scotch and whiskey ? Why is one expensive than the other or why does the taste differ according to the age of the alcohol? The blends and malts used to produce these distilled alcoholic beverages create all the difference. We have scooped out the answers into four simple differences so that next time you sound like an expert!

What Is The Best Time To Drink Whiskey

The Expert Jean LeNoir, founder, Le Nez du Whisky ‘For me, the best time to taste is late morning when your mind and taste buds are relaxed, and before lunch. Processing in the olfactory system is heavily dependent on whether we are hungry or full. When we are full, the smell is much less attractive.

Read Also: What Goes With Cinnamon Whiskey

Types Of Whiskey: Whats The Difference

The process for making whiskey depends on the type of whiskey and the country of origin. If youre new to drinking, or just a casual whiskey drinker, you may be confused by all the different types of whiskey out there.

Whiskey can be made from fermented grain mash or by distilling beer. The differences in whiskey types most come down to what type of grain is used as the base. Popular grains used are barley, corn, rye, or wheat, and sometimes the grains are malted. Weve broken down the differences between all the most popular types of whiskey below.